-

Asset Management – Manage asset categories

-

Cost Center Management – Manage cost centers

-

Work Center Management – Manage maintenance and service teams

-

Activity Type Management – Manage activity types

-

Functional Location Management – Manage equipment installation areas

-

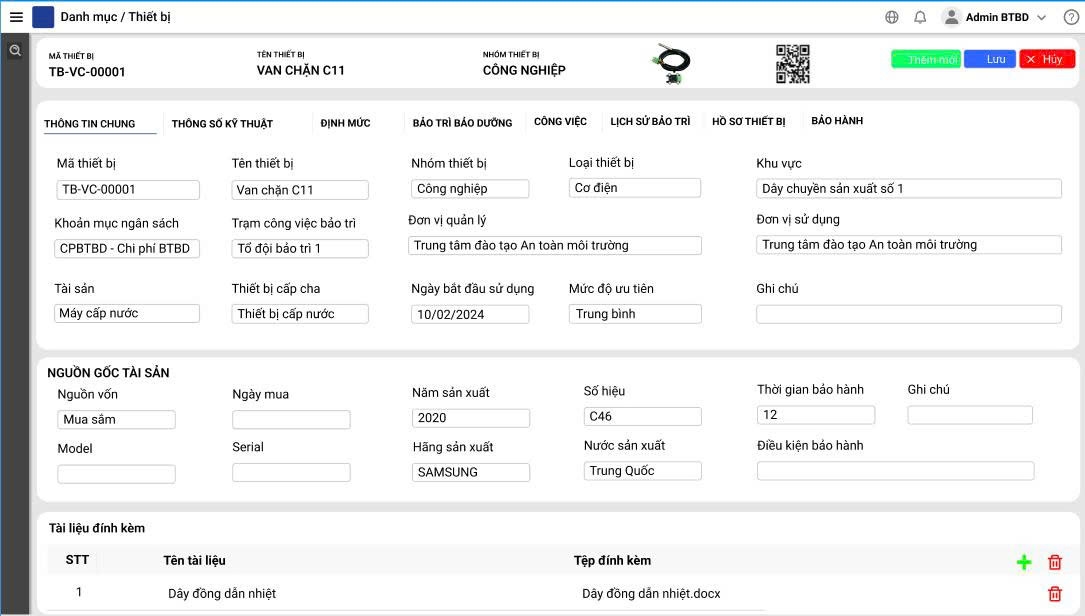

Equipment Management – Manage maintenance and service equipment

-

Equipment BOM Management – Manage component structures and replacements

-

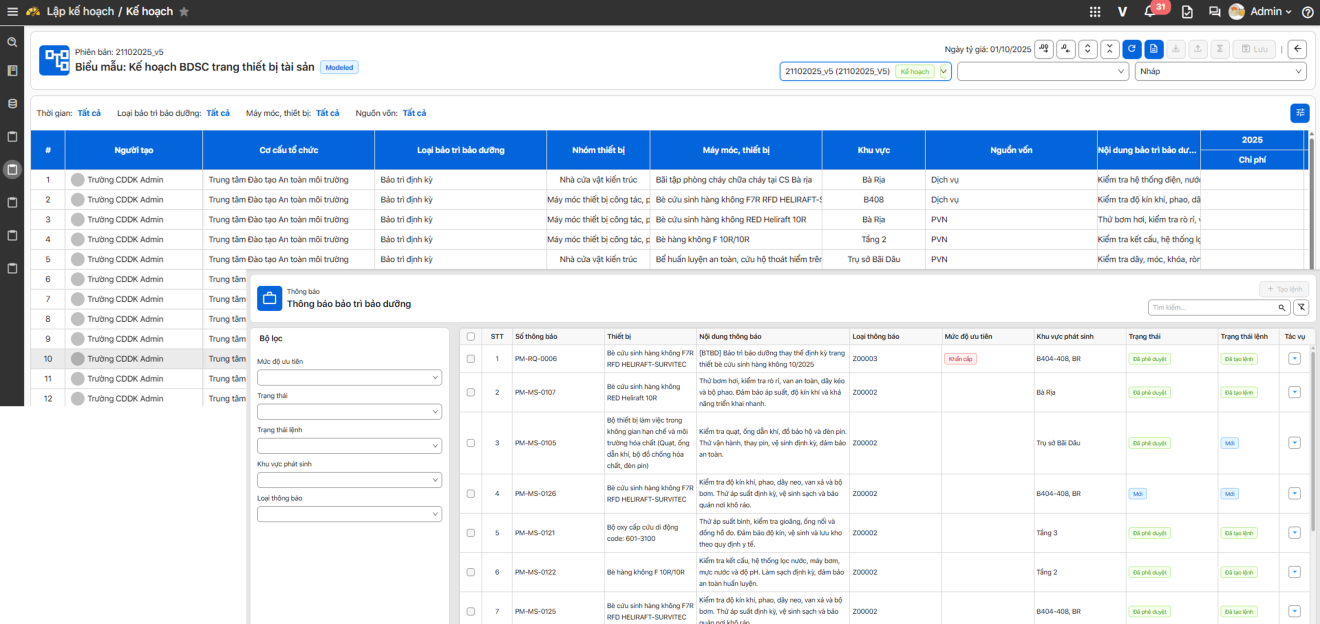

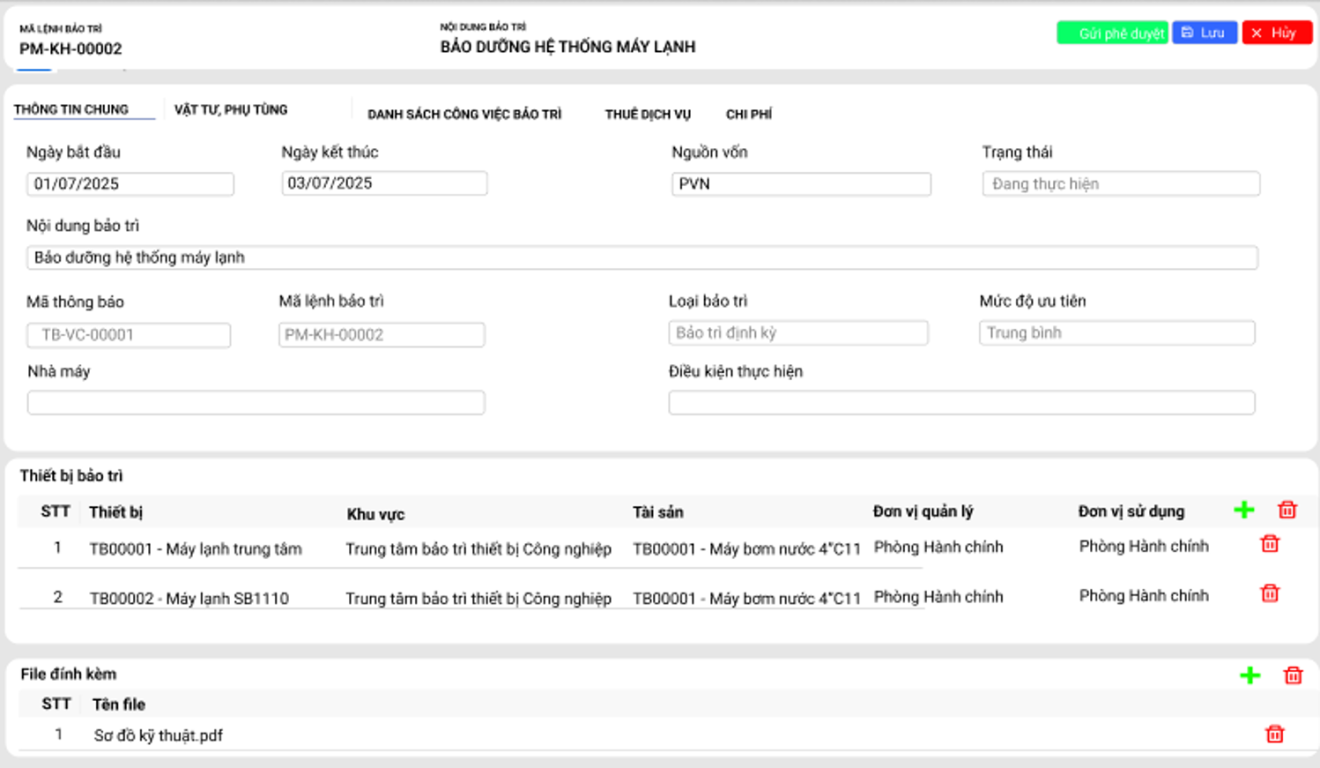

Task List Management – Manage maintenance and service task lists

Maintenance Management Solution

SiciX-PM

Smart solution for optimizing operations, managing assets, and improving enterprise efficiency

Phần mềm Quản lý Bảo trì bảo dưỡng SiciX-PM

Giải pháp tối ưu hóa quy trình vận hành, quản lý tài nguyên và tăng hiệu quả hoạt động của Doanh nghiệp

Tiếng Việt

Tiếng Việt