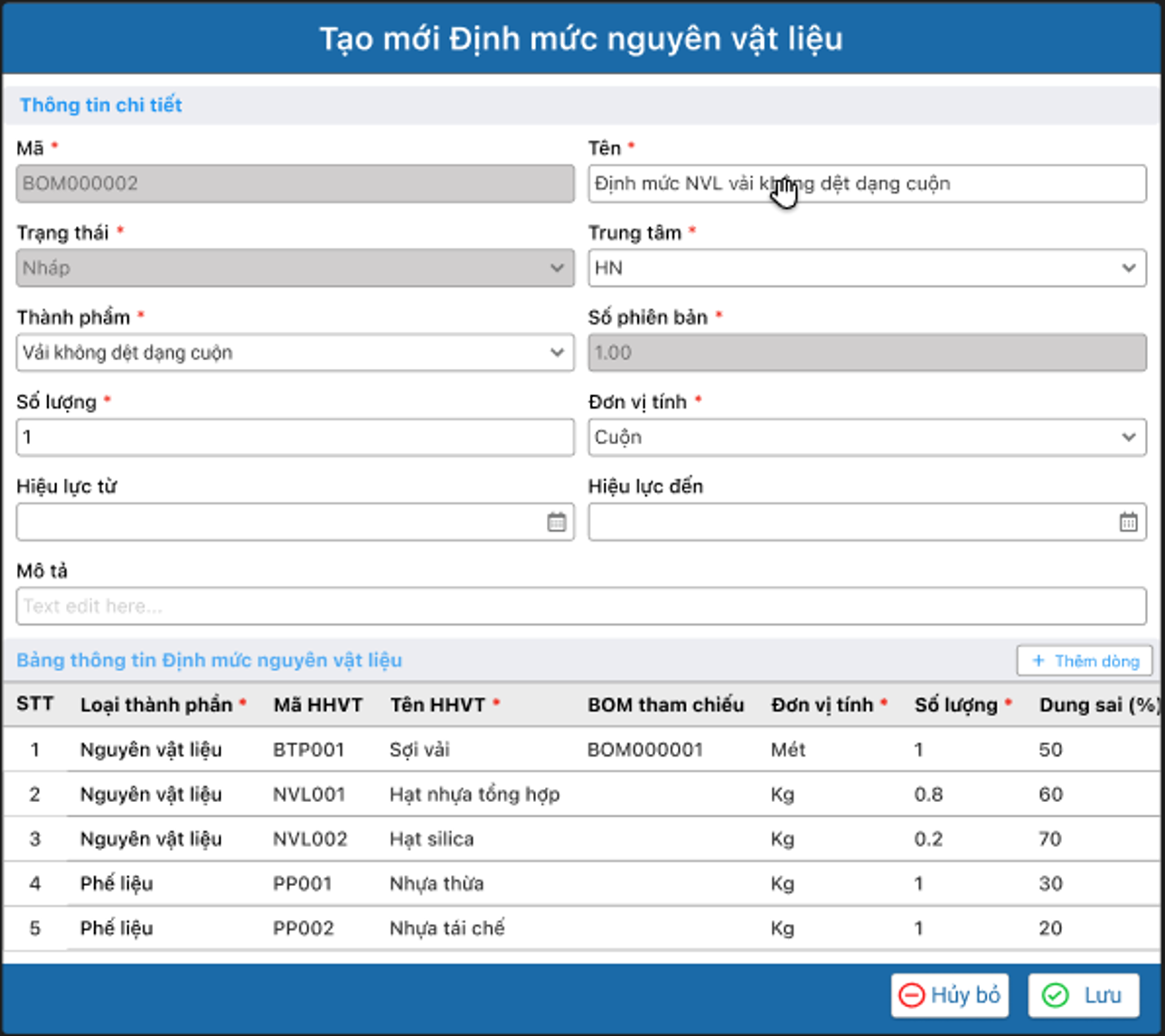

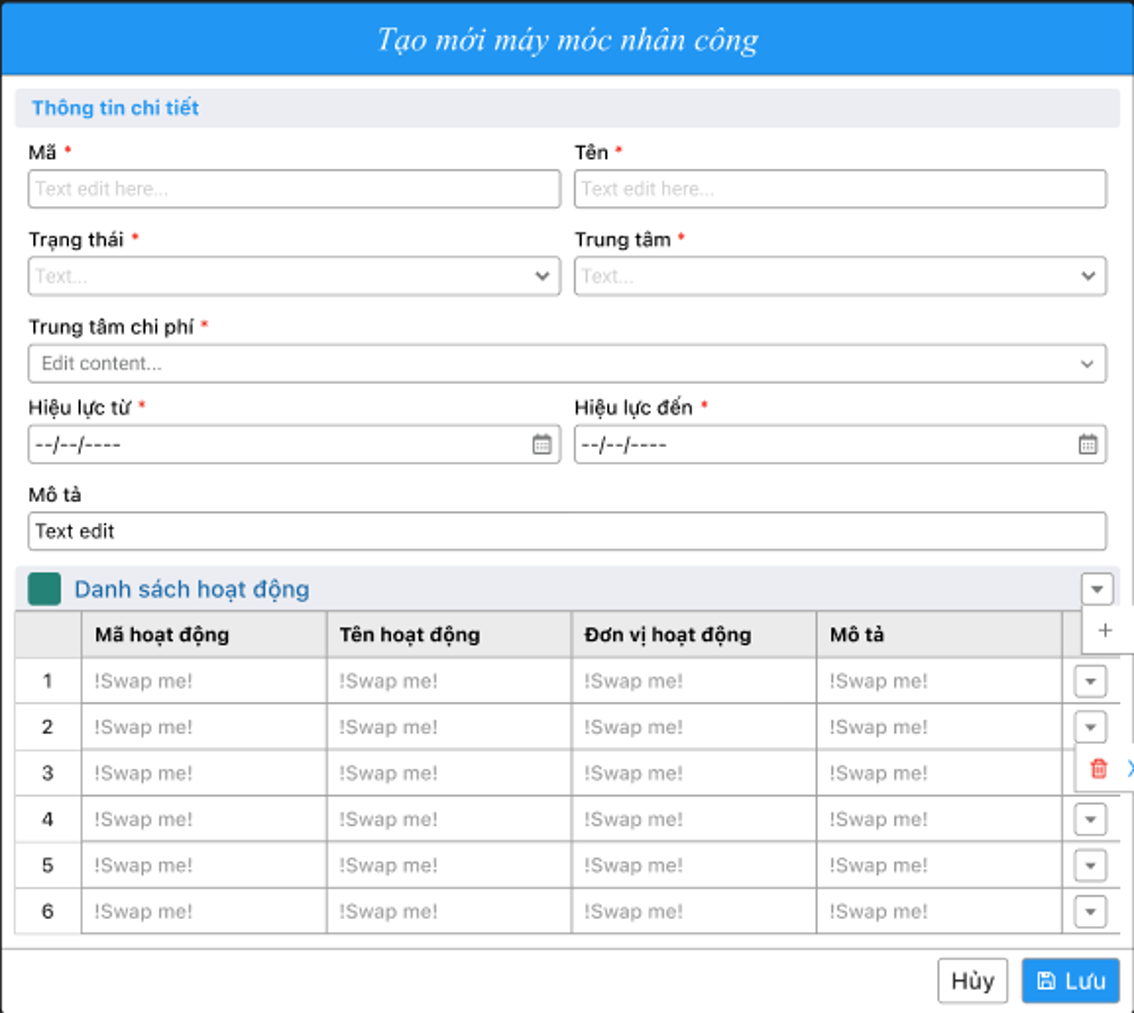

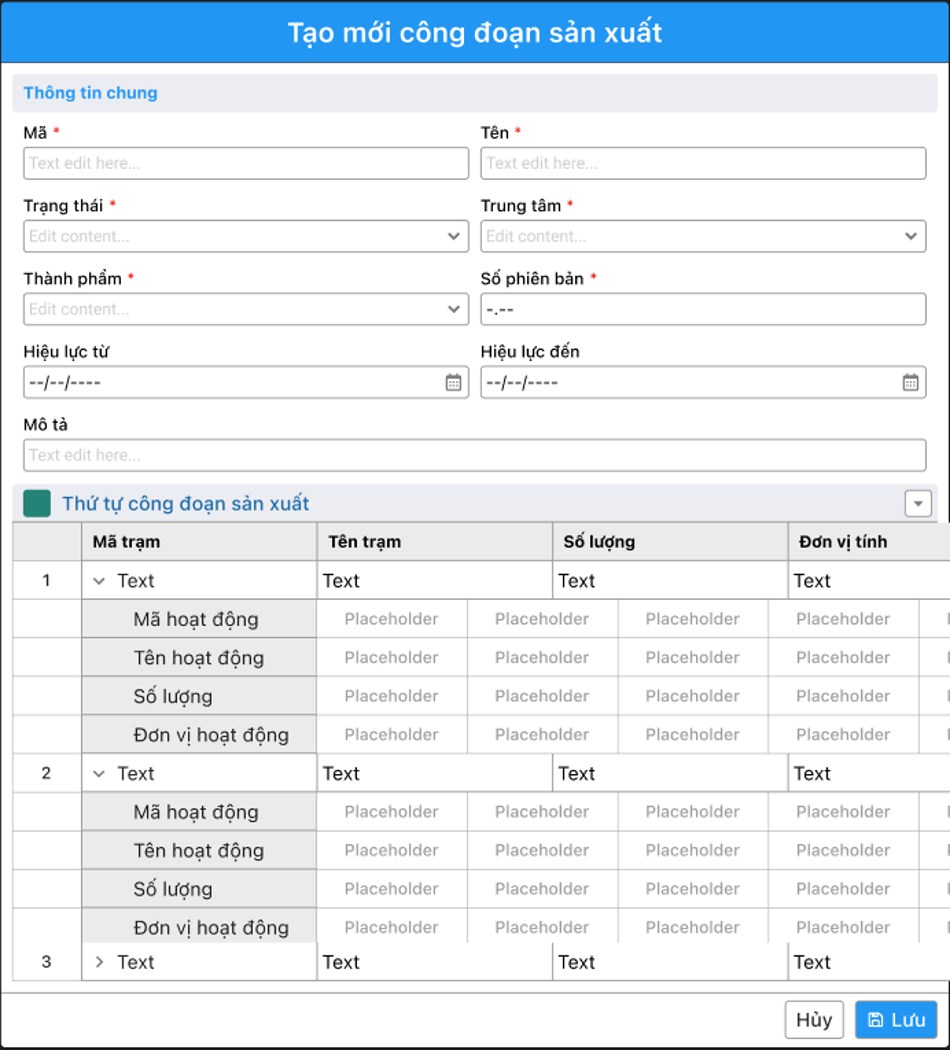

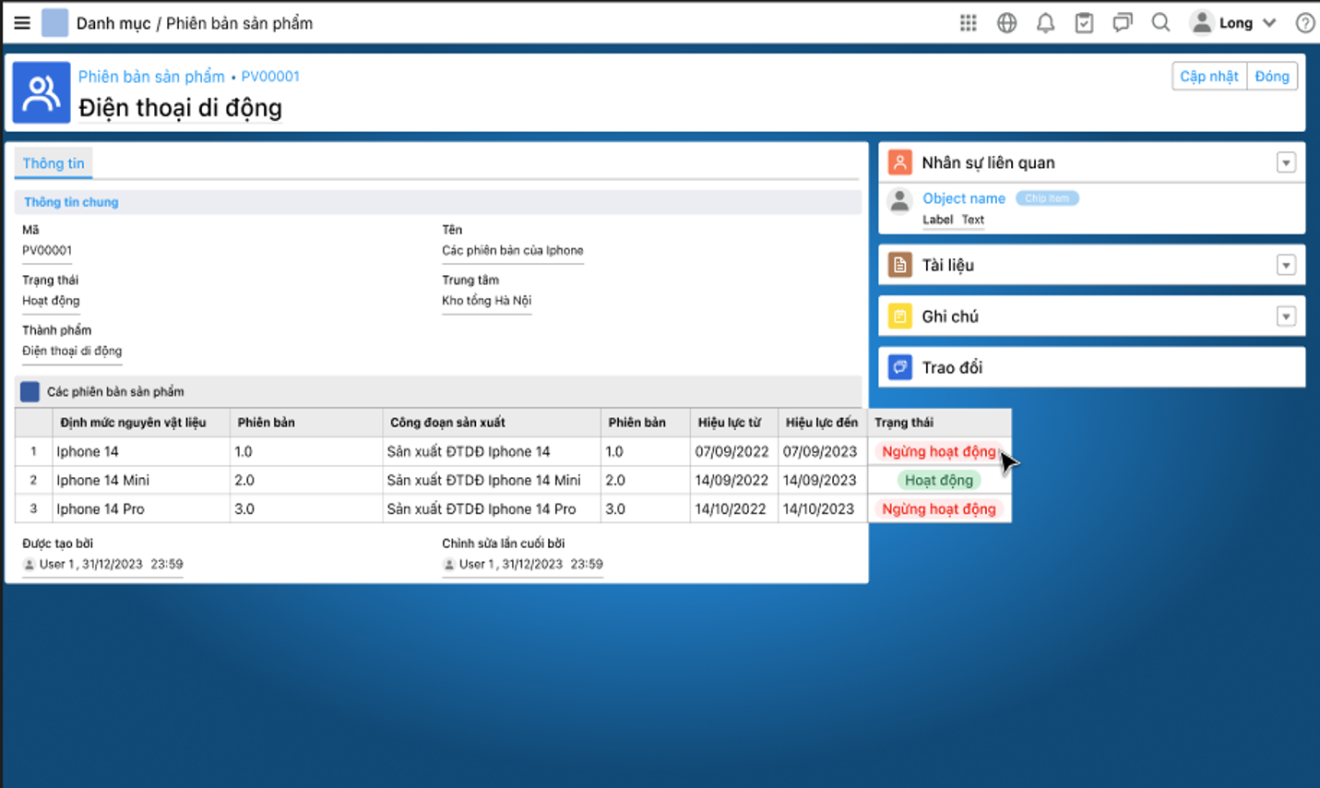

Allows businesses to create and manage both single-level and multi-level Bills of Materials (single BOM, multi BOM). The system supports configuring BOM details such as finished products, input materials, and production waste. It also enables the setup of key parameters including unit of measure, quantity, and tolerance levels.

Production Management Solution

SiciX-PP

Smart Enterprise Management Solution Based on Industry 4.0 Technologies

Tiếng Việt

Tiếng Việt